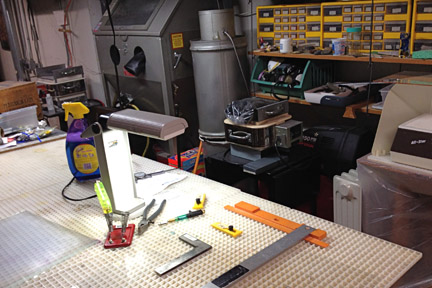

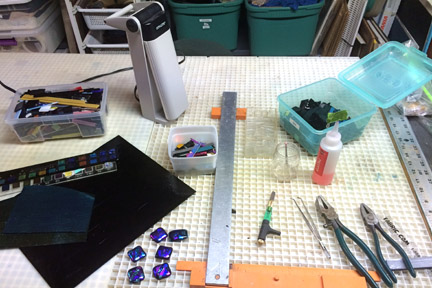

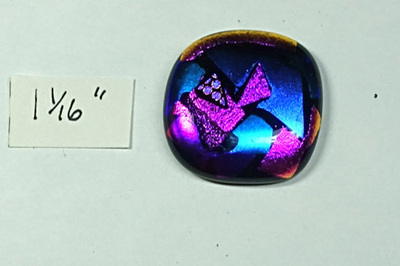

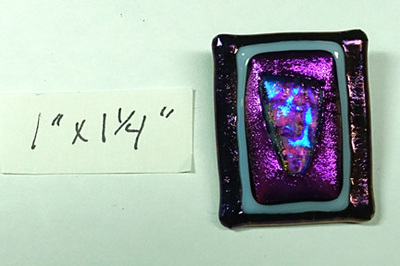

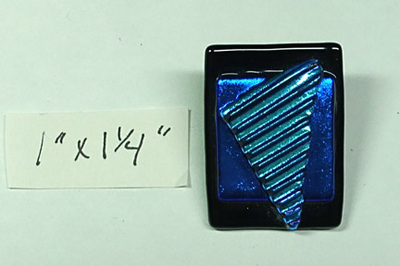

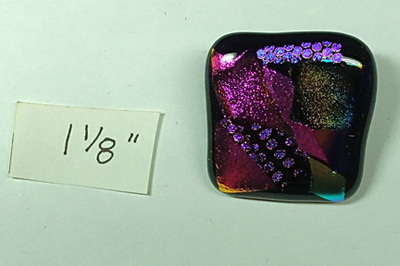

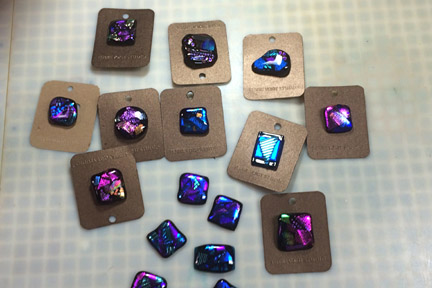

Samples of the project.

|

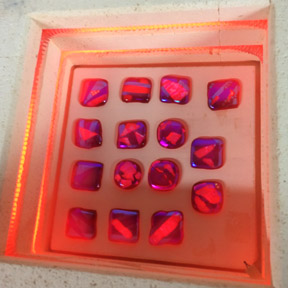

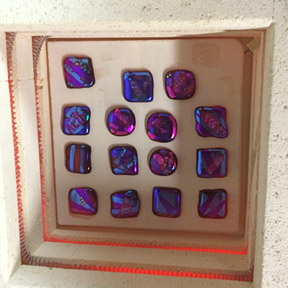

I had a small order to fill over the holidays. Usually I use my large kiln when I work with the glass, but with this order I only needed one of my small kilns. Each button is cut from compatible art glass, meaning that each piece of glass must expand and contract at the same rate during the melting and cooling process to prevent breakage. I built the buttons on a piece of thin black glass and added layers of dichroic glass (glass that reflects vibrant colors that often change as the light hits it). Melting of the glass: The pieces are set on a prepared kiln shelf. The kiln is heated up to 1400 - 1450 degrees F. In this photos the heating is just beginning. There is usually no sign of melting until the temperature of the glass reaches over 1350 degrees. The glass is checked periodically until the desired effect is reached. Once melted the glass layers now act as one piece of glass. The glass is cooled until its red glow eases into vibrant colors. The outside cool quickly, but the inside of the glass stays hot much longer. The temperature of the kiln is controlled to allow the glass to cool slowly and as evenly as possible to prevent breakage (annealing and thermal shock). The sizes of these buttons vary from 1 to 1 1/4 inches round or square. Samples of the project. The glass pieces are cleaned, shank applied, carded and ready to mail!

3 Comments

Mary Lou Batty

1/5/2015 07:11:07 am

Beautiful work!!

Reply

Beth Fowler

3/6/2017 09:07:37 am

Terrie,

Reply

Leave a Reply. |

Categories

All

AuthorI am Terrie Voigt, and I'm a textile and glass artist. I create art in both mediums and at times combine textiles with glass to create multi-media pieces or wearable art with glass closures. |

RSS Feed

RSS Feed