|

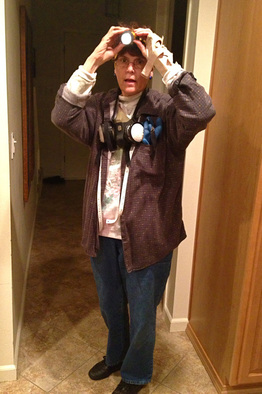

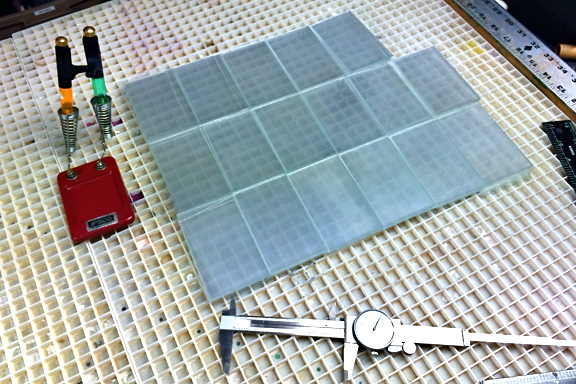

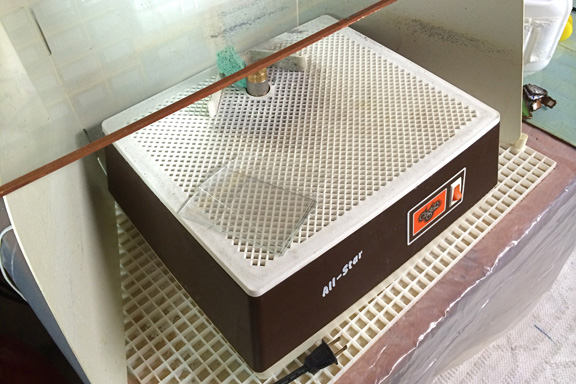

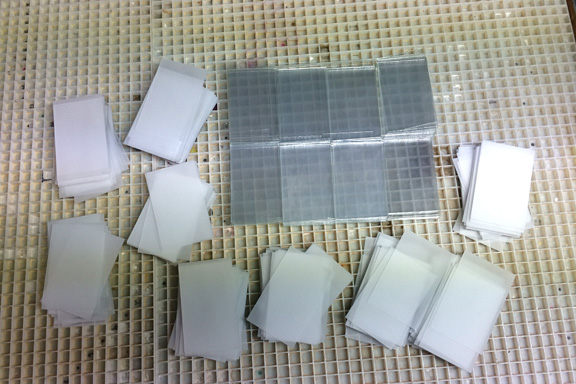

I sandblast on my glass screens, sculptures, buttons and jewelry. But for the last couple of days I've been working on my commercial glass work.  I cut and sandblast 2.51" x 4.04" pieces of micro thin glass. The glass pieces fit into a case that attaches to a microscope to diffuses the light. I like to think that on a very, very small scale I'm participating in the studies at universities and research in laboratories around the planet. I send the plates off with a blessing. Yesterday I cut around 340 pieces and inspected them for proper size. Today I started sandblasting. Each side of the glass is coated with a very fine grit - 220 aluminum oxide. For safety I use a great ventilating system and wear ear protection and an appropriate mask. I have sandblasted and inspected about half the glass pieces. Tomorrow I'll finish sandblasting. Then it's cleaning the plates and packaging them for my current and future orders. Okay, it's not quite as much fun as creating glass and textile art pieces. However, I've been making various microscope glass parts for over two decades. It's good work and it pays bills! Yes!

1 Comment

|

Categories

All

AuthorI am Terrie Voigt, and I'm a textile and glass artist. I create art in both mediums and at times combine textiles with glass to create multi-media pieces or wearable art with glass closures. |

RSS Feed

RSS Feed